Service Hotline

+8613912995166

Brief description:VPDM300plus planetary vacuum defoaming mixer is a planetary vacuum centrifugal mixer that can be used to mix various liquids or powder materials.

Model:VPDM300plus

Model:VPDM300plus Manufacturer:CHISHUN TECH

Manufacturer:CHISHUN TECH Update time:2023-06-30

Update time:2023-06-30 Visits:1160

Visits:1160TEL:+86 25-86795086 58000618

Skype:+86 139 1299 5166

Mobile:+86 139 1299 5166

E-mail:admin@nj-keyscience.com

http://www.dxb2222.com

VPDM300plus planetary stirring and defoaming machine is a planetary centrifugal mixer that can be used to mix various liquid or powder materials. The sample materials can be nano powder, conductive ceramics, battery powder or slurry, carbon nanotubes, oxide powder and metal powder. This device is particularly suitable for mixing some high viscosity materials.

application area

The mixing and stirring fields of materials for products in high, sharp and refined fields such as LED, LCD, medical devices, electronic components, nano powder materials, fine chemical materials, printing electronic materials, electronic packaging materials and new energy materials, such as phosphor, glue, silica gel, silver paste, aluminum paste, adhesive, ink, silver nanoparticles, silver nanowires, conductive silver glue, insulation glue, battery paste, etc.

Product Features

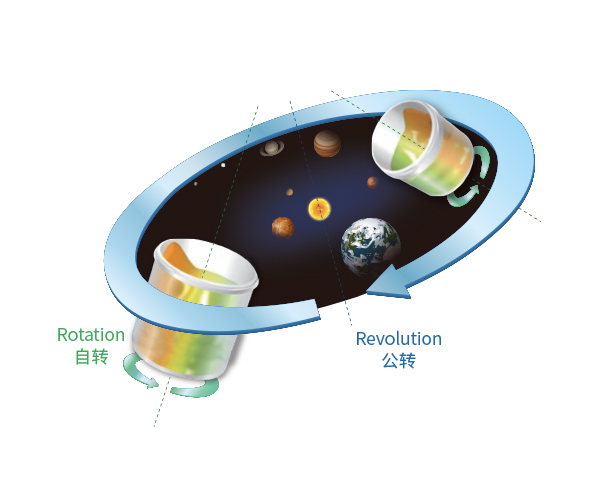

The material rotates and rotates within the container, achieving stirring, dispersion, and defoaming of high viscosity materials within minutes

High performance transmission: Adopting synchronous wheel transmission and its stable and low noise mechanical transmission, with low failure rate and long service life

No rod stirring, no pollution, and no damage to material properties

High speed revolution, high efficiency, and high viscosity glue can also be perfectly stirred evenly

Equipped with different cups and transition sleeves, large capacity equipment can choose small cups for easy conversion of size containers

According to customer requirements, various fixtures can be customized to meet customer requirements for direct use of different containers

technical parameter

Function: Mixing, stirring, and defoaming of various materials

Mixing method: vacuum rotation revolution non spiral mixed defoaming type

Mixing time setting: 1-30min

Revolution speed: 2200rpm (1-2200rpm can be adjusted arbitrarily, with an accuracy of 1rpm)

Rotation speed: 50% (revolution ratio varies with revolution speed) 1100rpm

Vacuum capacity: 0.5kPa~atmospheric pressure

Vacuum sealing chamber: made of aluminum alloy material with vacuum delay function, and the vacuum degree can be adjusted arbitrarily

Operating software system: Adopting servo control system, touch screen programmable

Balance mechanism adjustment: aluminum alloy material, precision grinding and casting integrated molding, pointer type infinite balance adjustment

Maximum mixing weight: 300g * 1cup (approximately 300ml, 82.7 * 90.5mm) Standard container 150ml, 300ml

Mixing container Max: at atmospheric pressure: 250ml, 300g, 300ml container; 200ml, 300g, and 300ml containers under vacuum

Safety design: top cover closure sensing, vibration sensor, speed sensor, emergency brake switch, overload protection device

Program settings: 1-10, can set 10 sets of program storage, staged mixing, customized speed, time, and vacuum degree; Each group of execution programs can be divided into 5 modes, with 5 stages to execute different time and speed vacuum degrees

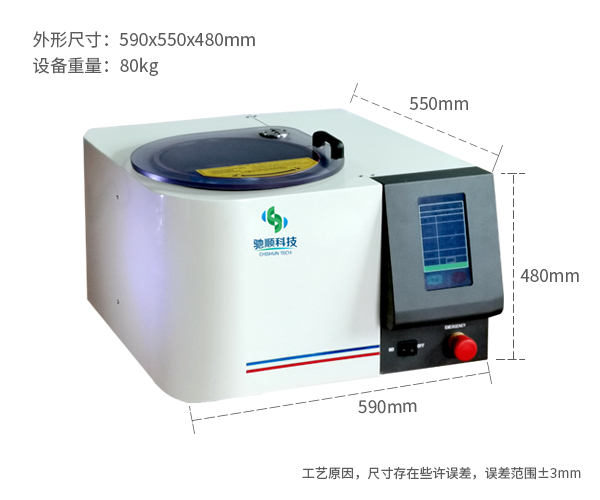

Equipment parameters: 550 * 590 * 480mm, 80kg

Wechat consulting

Copyright ? Nanjing Chi Shun Technology Development Co.,Ltd. Tel:86-25-86795086 58000618 58000718 E-mail: admin@nj-keyscience.com